Floating Deep-Water Wind Farms: Size, Power, Challenges.

Offshore fixed-in-place wind farms are not new, but they are providing renewable power in many locations around the world. But there’s a limit to the water depth — and thus distance offshore — that these wind-power sources can be located: about 60 meters (~200 feet) deep, typically corresponding to an offshore distance of a few miles depending on the ocean-floor drop-off at the continental shelf.

However, there is an alternative “grounding” system being explored for the deeper-water wind farms: floating towers. Instead of being inserted into steel tubes buried in the seabed as is usually the case for fixed wind farms, these generating turbines are tethered to the sea floor in various ways. One such floating system is the Hywind Scotland, in use since 2017, Figure 1.

Why go so far offshore? There are several reasons:

- The winds tend to be stronger and more consistent.

- Many of the suitable close-to-shore locations are already taken.

- It provides an opportunity to build bigger, more powerful, more cost-effective towers and generators.

- The environmental approvals are easier to get.

- The visual impact is far less; due to the curvature of the Earth (sorry, flatlanders!), these wind farms are not visible to observers once they are more than 25 to 30 miles away, depending on their height.

But — and it’s a very big “but” — the technical challenges of building these farms are considerable, for many reasons. Obviously, construction of these big structures in deep water is difficult, complicated, and costly, while maintenance is also a costly ongoing issue due to the salty sea water, fog, and storms, as well as the usual wear and tear. A rough guideline is that it costs about twice as much to build and maintain a floating system compared to a fixed-in-place non-floating of the same capacity. In an ironic twist, some of the electrical power generated by such systems may be used to power offshore oil and gas drilling platforms!

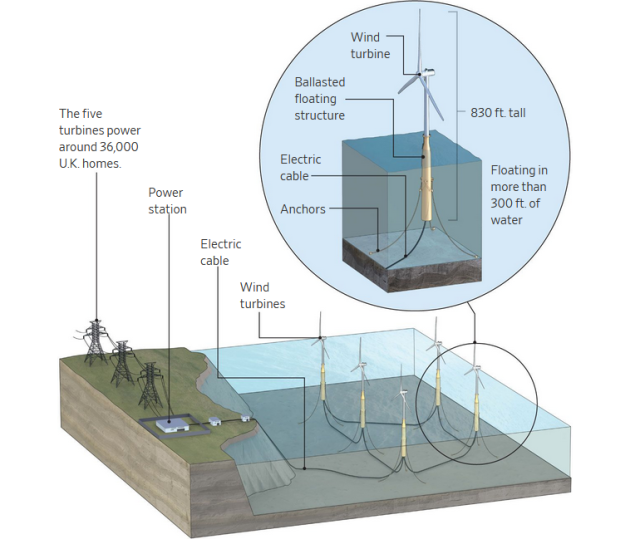

The Hywind Scotland with five towers and turbines is operated by Norwegian oil company Equinor ASA and is located in the North Sea off the east coast of Scotland, in water more than 90 meters (~300 feet) deep, Figure 2.

Its website provides these basic high-level specifics:

- The wind farm will provide enough electricity to power the equivalent of around 36,000 households.

- The farm consists of five 6 MW turbines with a total installed capacity of 30 MW, and a transmission voltage of 33 kV.

- The rotor diameter is 154 meters and overall height is 253 meters.

- The pilot farm will cover around 4 square kilometers in water depths varying between 95 and 129 meters.

- The average wind speed in this area of the North Sea is around 10 meter/second, while the average wave height is 1.8 meters.

- The export cable length to shore is 30 km (about 18 miles).

From mechanical, materials, and construction-engineering perspectives, even this “modest” arrangement is a very substantial undertaking. Other more ambitious floating systems are in the planning and financing stages.

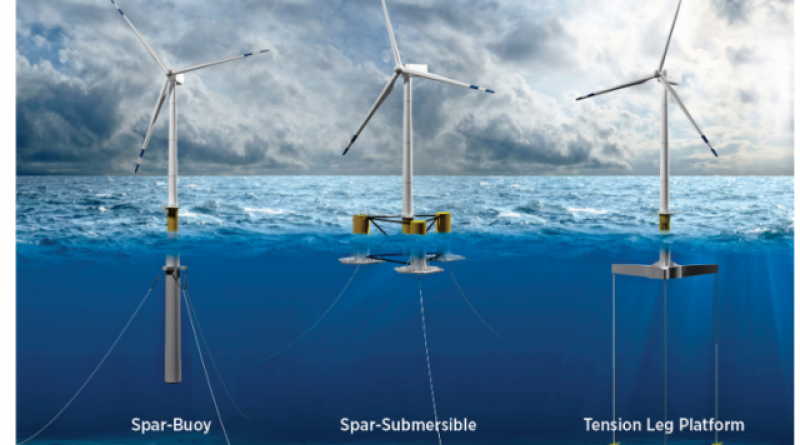

As with most engineering designs, there are alternative ways to solve a given problem such as anchoring the floating structure, Figure 3 (the IRENA (International Renewable Energy Agency) reference listed below has an interesting table detailing the pros and cons of the three options, as well as their demonstration status).

What about the electrical power output and transmission? We’re looking at some very big numbers here, no doubt of it. The Hywind Scotland project delivers peak power of 30 megawatts at 33 kilovolts, which corresponds to current of just under 1000 A. There are issues of insulation integrity and potential flashover, as well as the substantial cable needed to carry that magnitude of current with acceptably low IR loss (just do the math) and I2R self-heating along the 30 km run (fortunately, the ocean offers excellent convection cooling). One nice feature is that optical fibers can be incorporated into the cable design for a data link between generator system and land-based control center.

In addition to the cable-conductor diameter, the outer insulation and protective sheathing must prevent any ingress of water or moisture into the insulation, which would compromise its properties. This barrier needs to be thick enough to provide reliable protection but not so thick that it resists the cable’s flexing.Yet it must also withstand the constant dynamic movement without fatigue cracking.

Of course, the cable itself is only part of the story. It has to be terminated, and terminations for 1000 A conductors in these applications are not off-the-shelf catalog items. Three types of terminations are needed: one at the turbine side, one at the landing side, and the ones that splice together the outputs of the individual turbines before the single-cable link to shore.

There’s much more information available about these floating wind farms in the references below. Since much of the material is from proponents and boosters of these systems, the content tends to be upbeat, not surprisingly. These are ambitious and somewhat audacious projects, and it will be interesting to see how well they work out versus the plans and promises. Will these floating wind farms be successful, and by which metrics should that success be measured? It is too early to know, and the sample size is too small. They offer many potential benefits, but the technical and cost challenges are significant. It may turn out that their financial and performance viability is closely aligned with the specific location and available alternatives.

Will the harsh sea defeat these well-intended projects? Or will careful and comprehensive design, construction, and installation — plus lots of money, of course — make them generally successful? And to those engineers who worry about milliwatts and nanoamps, all I can say is this: you don’t know how easy you have it, in comparison!

References

- Equinor, What We Do

- Equinor, Hywind Scotland

- Global Wind Energy Council

- International Renewable Energy Agency (IRENA), Floating Foundations: A Game Changer for Offshore Wind Power

- U.S. Department of Energy, National Renewable Energy Laboratory, Floating Wind Turbines on the Rise

- The Conversation, Floating wind farms: how to make them the future of green electricity

- Windpower Engineering & Development, New cable designs are critical for floating wind turbines

- Greentech Media, So, What Exactly Is Floating Offshore Wind?

- The Wall Street Journal, Floating Wind Turbines Buoy Hopes of Expanding Renewable Energy

- The Wall Street Journal, Offshore Wind Farms, Big in Europe, Could Boom in U.S. Under Biden

25 April 2021

EE Times