Future houses to become material ‘banks,’ experts explain

This article is part of our special report Is there a role for concrete in sustainable construction?.

Europe’s efforts to adopt its construction and building sector and bring it more in line with climate and circular economy ambitions will entail a significant change in methodology instead of just using different materials than today.

Europe’s construction sector economy comes in at an annual turnover of almost €1 billion, but this comes at a price: Half of EU primary material use is done by the sector, and one-third of total waste comes out. Experts say this must change for the sector to become future-proof.

“The way we build absolutely has to change because we cannot continue to build for the landfill,” said Katharina Blümke, researcher at the Chair of Sustainable Construction at the KIT in Karlsruhe.

Because of the way construction works, added Elena Boerman, a fellow researcher on sustainable construction in Karlsruhe, “we have a building industry in which resources are brought in that end up coming out in the form of waste”.

Brussels is increasingly pushing to boost the circularity of the bloc’s economy, reducing waste and boosting Europe’s sustainability.

“We will no longer be able to afford to waste so many resources,” noted Blümke, adding that materials like zinc and copper are becoming scarce. And the “planetary boundaries” are also “felt in sand mining.” Sand is a crucial ingredient in concrete production, among other things.

The fact that resources go from construction to landfill calls for a new approach to the subject, she said.

“Use other, single-variety materials, choose construction methods in such a way that materials and components can be connected to each other in a degradable way.”

Much like Lego bricks, the world-famous Danish “toy,” the two experts argue, buildings should not be the end of a material’s life in the value chain.

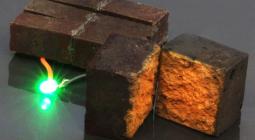

“We have to look at buildings as material stores,” said Boerman. If you have “a building life of X years,” then material would be “stored” in the building. “After that, you can take it out again. Just like a bank. This is how circular building works,” the German expert explained.

New material revolution?

Traditional ideas of sustainable construction, a switch to materials that grow back like wood, appear increasingly outdated.

“Building with wood is one possibility, but it is not the panacea,” said Blümke. According to the expert, wood is deemed as a high-value material that should be used as efficiently as possible given its important role in other sectors.

“We can’t just say we’ll build everything in wood, and then we’ll have solved all the problems,” she added. Particularly careful consideration should be given to the use of wood in composite boards – chip boards commonly found in many European households today.

Once a traditional chipboard is created, wood and glue are inseparably mixed in the production process. The biomass is then lost as a material and will ultimately be landfilled, as glues tend to make it too toxic for use as fertiliser.

The two experts are especially interested in the potential of bio-based insulation materials.

“Seaweed insulation has similar U-values as wood insulation, but firstly it is pure, and secondly it can be easily applied. Its natural texture makes it unattractive to pests,” says Blümke.

Given the host of options growing out in the wild, “it doesn’t make sense to settle on a single insulation material,” explained Boerman.

“There is a huge variety of ecologically based insulation materials that are recyclable” with similar insulation efficacy as traditional insulation materials, she added. “These would be flax, hemp, jute, and reed.”

The uptake of the new materials has been slow, though.

“There is a huge variety of ecological insulation materials and yet the application rate in Germany is less than 10 percent,” according to Boerman.

Introducing new materials to the industry would not spell the end of legacy products, though, she stressed. “One material is not enough. We need a variety. Materials must be used in specific places where they make sense,” Boerman noted.

“We will never be able to do without concrete, at least as things stand today. But concrete must become cycle-friendly. So we need real concrete recycling, where aggregates and all other ingredients come out again at the end and then new concrete can be made from the same material.”

“Then it also makes sense to use the concrete in certain sensible places in building construction and civil engineering and to take it out of the building stock again,” Boerman said.

[Edited by Zoran Radosavljevic]

cover photo: Future ways of construction are expected to turn buildings into temporary material "banks" instead of being part of the pipeline into the landfill, two sustainable construction researchers explain. [Shutterstock/sylv1rob1]